Knowing the crisis, deeply analyzing internal problems, taking into account the overall situation, and striving to complete the annual goal - a side note on the company's work

【Summary description】Since the beginning of this year, affected by the sharp rise in the price of raw materials and the impact of the epidemic, the company has been struggling to survive and seek development. Although it has achieved certain

Since the beginning of this year, affected by the sharp rise in the price of raw materials and the impact of the epidemic, the company has been struggling to survive and seek development. Although it has achieved certain operating performance, there is still a long way to complete the annual goals and tasks, and the operating situation is extremely severe. , the difficulty of development is extraordinary. In order to regain the time caused by the epidemic and the losses caused, the company timely implemented the unified deployment of Gansu Electric Group's "work hard for 40 days and strive to sprint for the annual goals and tasks", and strived to increase production capacity by strengthening management and promoting reform. Efficiency, reducing operating costs, improving operating performance, and implementing a management and control strategy that integrates top and bottom links and internal and external integration, and strives to ensure the completion of annual goals and tasks.

In order to fully complete the current work, escort production and operation through the improvement of management level, and provide basic support for the company's transformation and high-quality development, on the morning of November 22, Gao Yuzhong, secretary of the company's party committee and chairman of the board, presided over the management department's 2022 operation. The management work seminar emphasized that each management department should deeply analyze the problems existing in the department, and focus on the "2+N" work strategy (that is, focusing on sales and technological innovation, focusing on improving quality and efficiency, quality control, cost control, and internal management). Supported by N measures to enhance the core competitiveness of the enterprise), it will strongly support the completion of the annual goals and tasks, and ensure the implementation of various tasks in 2022.

The meeting emphasized that all departments of the company must have longer-term plans, more pragmatic measures, and a more open vision. It is necessary to clarify job responsibilities, strengthen operational data analysis, do detailed cost accounting, do a good job in risk assessment, use quantifiable and actionable indicators as a powerful tool for performance control, innovate work, improve performance, and provide decision-making for the company's high-quality development Basis: We must resolutely implement the "customer-centric" development concept, face up to shortcomings and gaps, strengthen crisis awareness, first achieve breakthroughs in thought, and then make a difference in action, strive to turn crises into opportunities, and make every effort to sprint for the year Target task, hand over a qualified answer sheet.

The magnet project is a key project for the company to achieve breakthroughs in new industrial fields. Since the cooperation with the Institute of Near Physics, Chinese Academy of Sciences in the second half of 2019, it has provided various electromagnets, electromagnetic coils and test terminals for Lanzhou Kejin Taiji New Technology Co., Ltd. of the Chinese Academy of Sciences. Yutai has made important contributions to the localization of heavy ion therapy tumor equipment accessories with independent intellectual property rights in my country. In order to straighten out the production process of the magnet project and strengthen the special management, in mid-November, after the company's research and decision, the magnet business department was specially established, and professional cadres were selected to set up a management team, and key employees with outstanding skills and rich experience were selected to form a production team. Guarantee the smooth progress of each batch of contracts of the magnet project. After the establishment of the Magnet Business Department, it has taken over the organization method composed of temporary personnel from the production security department and other departments, and the scattered management has achieved centralized, unified and intensive management. The establishment of the business department will lay the foundation for the mass production of magnet products, and will also effectively help the company to improve its business performance and accelerate the completion of annual goals and tasks.

The large and medium-sized motor manufacturing department closely follows the annual production and operation goals, focuses on key contracts, and is guided by the improvement of quality and efficiency. In the connection of each process, the dispatching command was strengthened, and the production capacity and task completion of each team were scientifically analyzed, and the task was fully satisfied, the production capacity was fully released, and the processes were connected in an orderly manner. Established and gradually improved the time node control mechanism, strictly followed the production plan, accelerated the batch construction progress step by step, tried every means to squeeze the transfer time, and pressed the "fast forward button" for production. In November, while ensuring the rapid progress of production, the four key quality indicators, such as the qualified rate of gold processing quality of large and medium-sized motor parts, the qualified rate of stator and rotor cores, the qualified rate of finished motor assembly inspection, and the qualified rate of one-time test of finished motors, were all On the original basis, it has increased by 1 percentage point, and the product quality has been steadily improved.

All employees of the small generator manufacturing department actively responded to the company's call,unified thinking,raised awareness,and established the collective concept of"paying for yourself and protecting the overall situation".Taking safety production,product quality,and fixed management as the starting point,we will go all out to sprint towards the annual goal.The manufacturing department has formulated a scientific operation plan based on the production status of each section,adopted key organization and key arrangements for key products,and strengthened quality tracking to ensure that production is not relaxed,the progress is not delayed,and the quality is guaranteed.While making every effort to do a good job in production,the manufacturing department closely cooperates with the scheduling of each section and the team leader,and earnestly carries out fixed-setting management.Daily cleaning and weekly cleaning ensure the tidying of the operating environment,creating a comfortable environment for busy production.

The Riveting and Welding Division has formulated a work plan of"Riveting with full energy to grasp the progress,and busy with production at full speed"to fully guarantee the supply of raw materials,production sequencing,and progress monitoring,and use practical actions to grab time,progress,and tasks for subsequent production.The department buys time.The business department held a special production support meeting and a mobilization meeting for resumption of production and production,and issued a mobilization order.For some products that were insufficiently supported by materials due to the impact of the previous epidemic,all employees were concentrated on tackling key problems.Recently,more than 190 new products of Xiaofa have been launched successively.,75 sets of large and medium-sized motor bases and more than 150 sets of motor product end cap production plans,started the sprint to tackle the annual target task.The employees in each process are full of energy and enthusiasm.The department consciously works overtime with more than 30 employees every day.Although the weather is cold at night,there is a hot scene everywhere in the department.

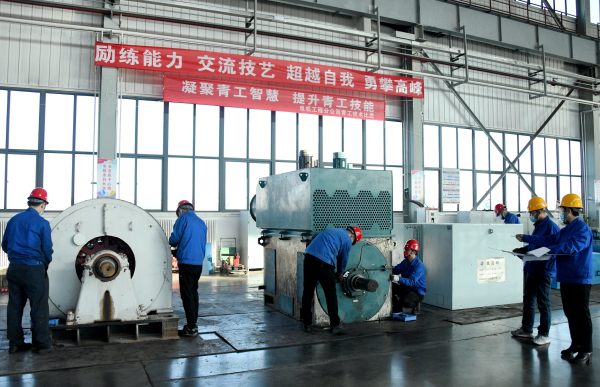

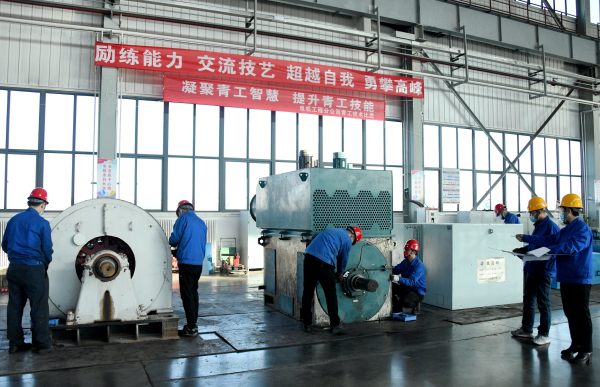

The Electrical Engineering Branch took the opportunity to carry out the"Young Workers Job Skill Competition",focused on key contracts,and focused on improving the skills of young employees,thereby improving the work quality and efficiency of all employees,and promoting the completion of annual goals and tasks.At the competition site,young employees were full of energy and focused,and their usual hard training was also concentrated.The process,standards,speed and passion became the main theme of the competition,and the event was a complete success.There are many young employees in the engineering branch.Through skill competition,it has achieved"improving skills and promoting production"with two birds with one stone,which has also created conditions and laid a foundation for the next step to speed up production.

Near the end of the year,time waits for no one,and the situation is urgent.Only by concentrating,going all out,thinking in one place,and working hard,can we achieve our goals and achieve success.The cadres and employees of the company unanimously expressed that they should improve their positions,strengthen their understanding,thoroughly implement the company's decision-making and deployment,and solidly promote various work arrangements.Make due contributions to the goals and tasks.

The kick-off meeting of the carbon neutralization research project in the field of energy saving of electrical equipment was successfully held in Shanghai

The kick-off meeting of the carbon neutralization research project in the field of energy saving of electrical equipment was successfully held in Shanghai Carbon neutrality: a four-decade national exam

Carbon neutrality: a four-decade national exam The Fifth Meeting of the Eleventh Council of the Chinese Society for Electrical Engineering and the 2021 Work Conference Held in Beijing

The Fifth Meeting of the Eleventh Council of the Chinese Society for Electrical Engineering and the 2021 Work Conference Held in Beijing

Tel0931-5150442

Tel0931-5150442 QQQQ

QQQQ Cooperation574947494@qq.com

Cooperation574947494@qq.com Consulting18609315000@163.com

Consulting18609315000@163.com